CNC machining is a highly advanced form of making various devices, machines, prototypes or parts. CNC machining has different categories for refined and easy production processes. The type of CNC machining category selection depends on the product being manufactured. 5-axis CNC machining is the latest in its form and provides 5 axes for the rotation of the cutter.

Benefits of 5-axis CNC machining:

There are several benefits of 5 axes which have won the era over the 3 and 4 axes. The following are some important features of this setup;

Efficiency:

When parts of the prototype are clamped on a 5-axis CNC machine once, the process proceeds further. This results in high efficiency, better quality and durability of the prototype.

This helps in reducing costs by lowering fixtures and working hours. As the waste decreases, the process becomes viable and increases the output quickly.

High-quality prototype:

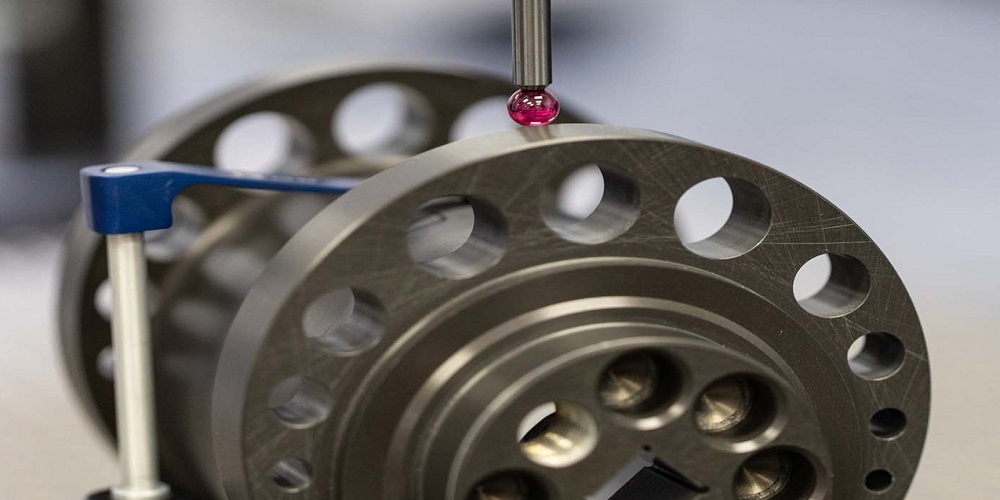

The manufactured part comes closer to the cutter by increasing the number of axes. Resultantly, blades become shorter, which helps reduce the vibrations to a great extent. At high spinning speeds, vibrations become damped, giving a fine and smooth finish to the product's surface.

High accuracy with shapes:

Ordinary 3-axis CNC machines are used to increase the time and cost of the process. This happens because 3 axes require more time to process the prototype parts. A 5-axis machine can work with perfect arcs and angles and maintain a complex geometrical design. However, these machines are expensive but do not impact the cost of large quantities of production units.

No need for extra fixtures:

A 5-axis CNC milling machine does all the clamping at once, so the need for extra clamping and fixtures reduces. Thereby, it increases production in a short time by reducing the chances of error.

Uses of 5-axis CNC machine:

5-axis machine systems have revolutionized the era of upcoming machines. New machines and devices have advanced features which have eased the overall industrial process.

Medical devices:

In the medical department, stainless, perfectly carved devices are required to fit correctly in the human body. Other machines are used to examine the human body; these machines also need high quality. 5-axis CNC machines help in multi-dimensional easy cutting and forming.

Automotive devices:

5-axis provide high precision in aerospace and automotive parts. Mechanical parts require perfect coordination among them, which is provided by the 5-axis machines. Faster production of the batches owes to these machines.

Building devices:

CNC machining systems help develop the machinery according to the required design. Door frames and other architectural work require accuracy to avoid errors in performance. A minor mistake in the cutting and size of a component may deteriorate the building structure.

High energy requiring industry:

Petrochemical and military industries require industrial products in oil refineries and heavy-duty manufacturing vehicles. Weapons are necessary for military purposes, and minor structural irregularities may render the weapons useless.

So, modern technological machinery requires 5-axis CNC machining for better function. CNC machining has been proven a very successful and helpful process and has eased our lives.