Deciding on the materials to use and how to use them is complicated. It is a tedious process, but it also costs a lot of time and money — factors challenging to manage. CNC Machining Capabilities can help you create your custom parts, invent your invention and do more with less.

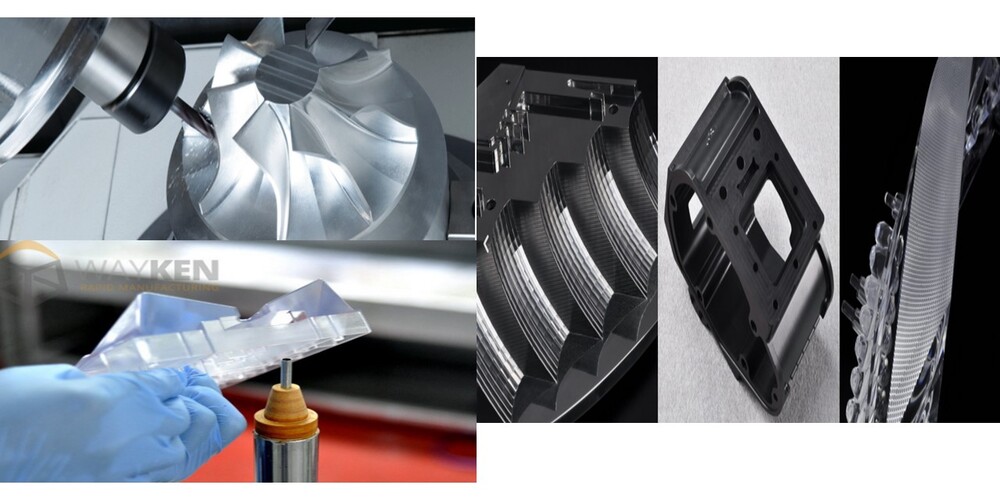

With the CNC machining capabilities of 2-axis or 3-axis mills and 5-axis, Wayken can provide machining services for your company, no matter what the project. Save time and money with our CNC Machining Capabilities service. We can design and produce PCBs, hoods, or anything else in just 24 hours!

Let’s find out why this method is more capable than any other method.

Versatility

The CNC machining system is versatile because it can process almost any material, small and large diameter, long, short, and configuration parts. With CNC machining systems, you can make complex parts with perfect precision in the shortest possible time. It also helps to produce high-quality parts (accuracy, smoothness, and finish), reduces labor cost, and increases the production efficiency.

CNC machining technology has more advantages than other technologies in the past. It’s possible to make multiple components simultaneously, which saves time and cost and improves the quality of the final product.

It also provides flexibility in product design, allowing customers to customize their products according to their needs without compromising on performance or function

Reliability And Consistency

CNC machining system has many advantages, that is why it is becoming popular with every passing day. The main reason is its resistance to failure, consistency, and flexibility. But to get all the benefits you need to buy good equipment.

There is almost zero chance of making mistakes, and you will always get the same results from the machine. CNC machining systems are reliable, consistent, and optimized for efficiency.

They can be used in a wide range of applications – from mold making to the final production of a fully assembled product. The software developed by our specialists enables maintaining a high accuracy level in all processes, which guarantees quality parts produced by the computerized equipment.

Highly Adaptable

CNC machining system is highly adaptable to different tooling. It is easy to tell the needed tooling and how long it will take to prepare the process. It can be done in days and weeks instead of months.

Whether your business is making parts for cars, home appliances, or electronics, CNC produces components that match the quality of those made by human hands but at a much lower cost.

CNC machining is an automated method of manufacturing products where you can use various materials as needed. By combining the CAD-CAM and CNC router technologies, you will get many options for designing and manufacturing any product.

Eliminate Variances

Variances lead to product defects, scrap, and rework, reducing manufacturer profits. OTTO can design CNC machining operations that eliminate these variances and provide more consistent part quality while reducing your manufacturing costs.

The CNC machining system will enable you to eliminate the standard human error in manual machining, which is a significant source of variation. Over time, CNC machining will become a standard application in all production areas because it improves the quality of your output and saves money.